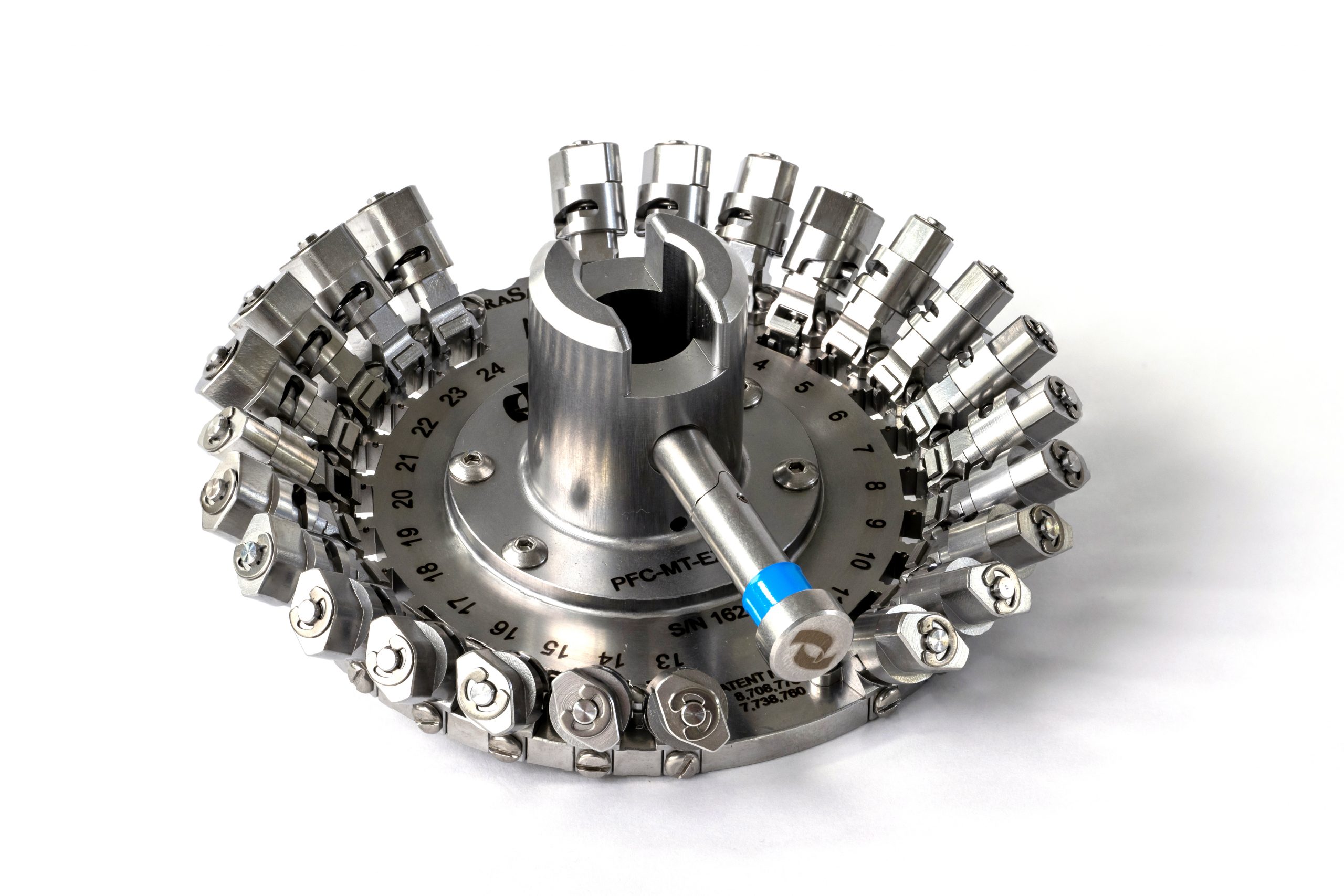

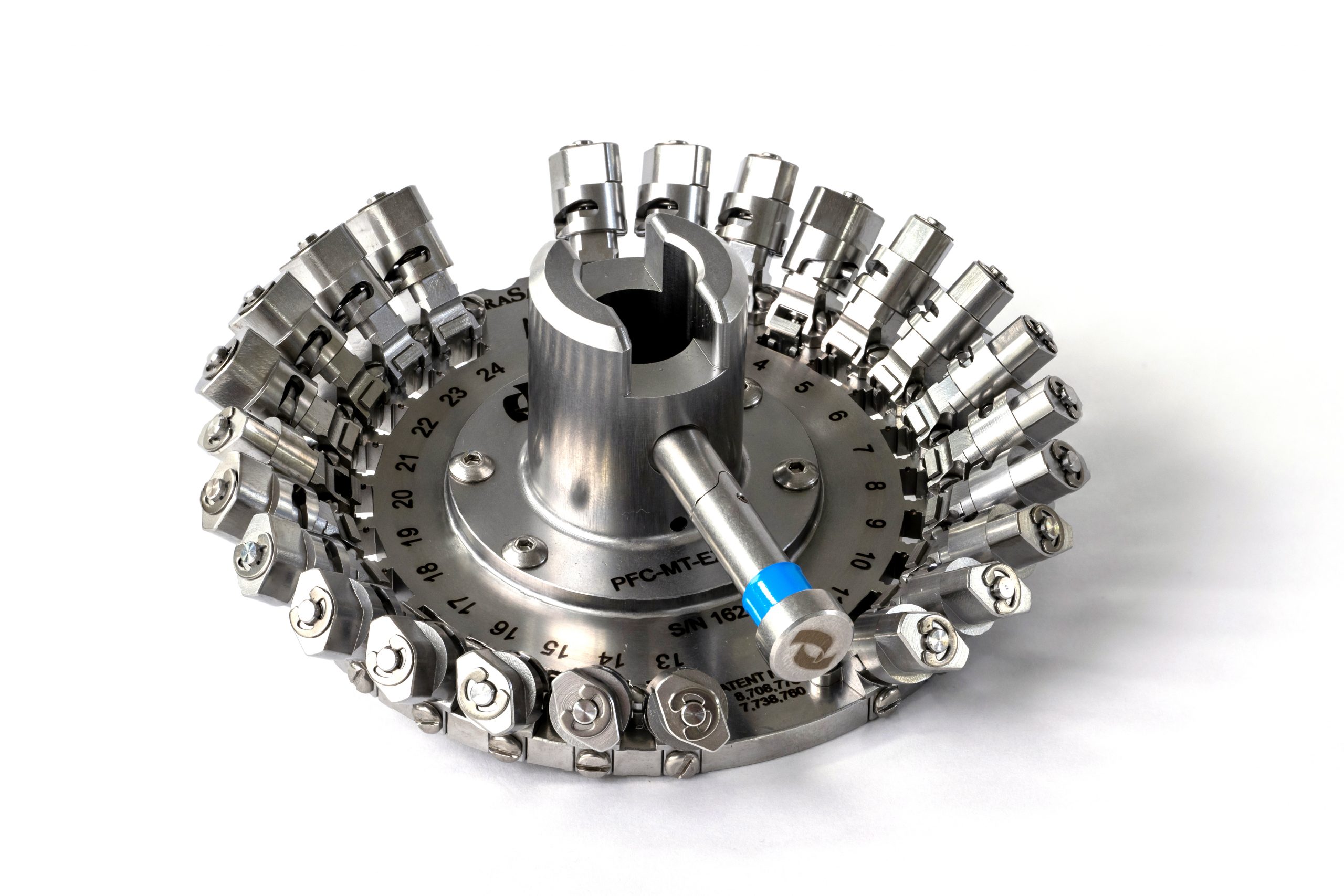

Our customers often expressed concern about the cost of abrasive film used during the polishing process. Domaille’s team developed the AbraSave® (abrasive saving) fixture line as a result of studying this issue.

The AbraSave® concept is based on mathematics. In polishing fixtures, all connectors are radially spaced and located at the same distance from the fixture’s center. This configuration wears out a consistent pattern on the polishing film, while other areas of the film go unused. This is changed by AbraSave® technology, which gives each fiber its own path on the polishing film, which we call Unique Path Technology. Here’s a comparison chart. Unique Path Technology reduces polishing time by 50% and extends abrasive film life by 90%. Savings on abrasive films.

The AbraSave® technology is also beneficial for multi-fiber connectors like MPO and MTP. The center fibers are usually longer than the outer fibers when these connectors are polished on standard equipment. With Unique Path Technology, we minimize protrusion height variation, greatly improving yield. AbraSave® technology can be applied to almost any cable or connector type.